Description

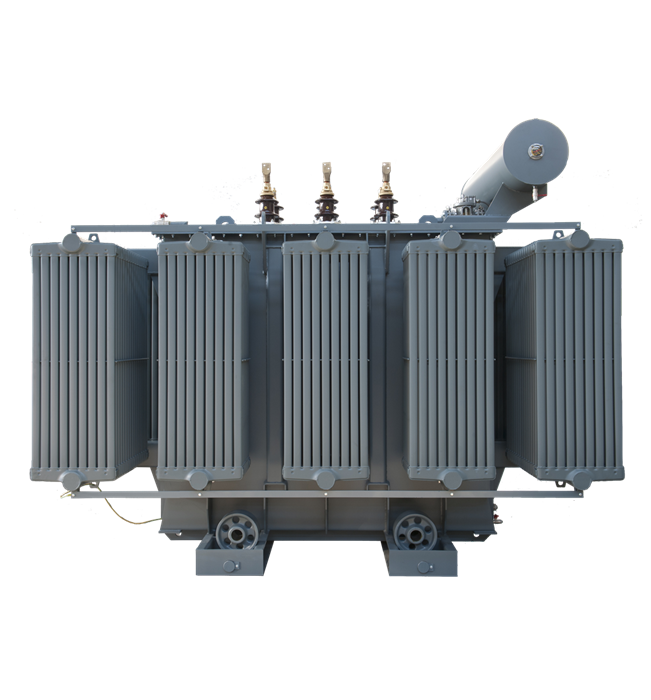

SIRMET ELETTRICA manufactures electric oil-immersed distribution transformers with a power range from 50KVA up to 25MVA and a maximum working voltage of 132KV.The core is made of low-temperature cold-rolled grain-oriented steel with a 45 ° cut. The LV windings are normally made of tape (copper or aluminum) to ensure better resistance to electrodynamic stress in the event of short circuits. The turns are insulated from each other by an insulating material composed of pure cellulose paper.

The HV winding is normally made of enameled copper wire or copper strip covered with pure cellulose paper; all the insulating materials are of the highest quality and undergo rigorous checks before they are used.

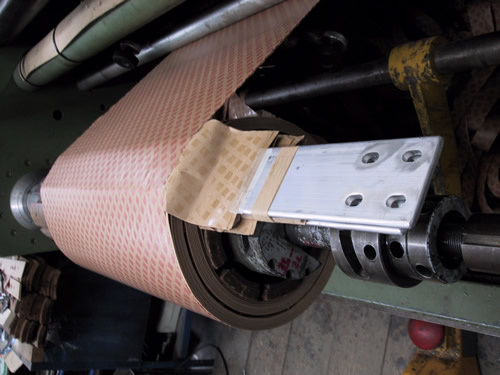

To obtain perfectly homogeneous and symmetrical coils, which are essential conditions for a long-lasting operation of the transformer, the windings are made with the use of computerized machines that ensure a correct conductor traction. Moreover, suitable channels made in the primary and secondary windings allow the insulating liquid to transfer the heat from the windings to the cooling system placed on the transformers tank, thus obtaining an optimal temperature.

Features

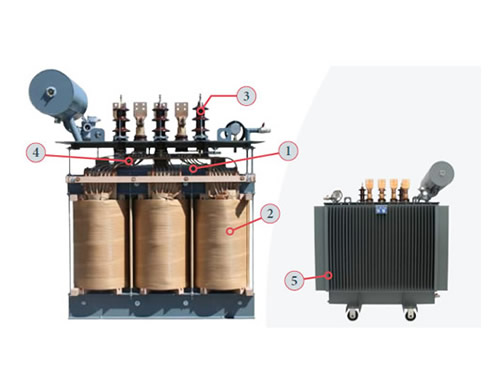

1.CORE

The core is manufactured with grain-oriented silicon sheet with low losses, with 45° cut and step-lap assembly in order to reduce noise.

2.WINDINGS

Windings are realized with computerized machine able to guarantee the exact traction of the conductor and obtain uniform and symmetric coils.

LV WINDINGS are manufactured in bands (copper or aluminum) to guarantee an improved resistance to electrodynamic stress in

case of short- circuits and with pure cellulose paper isolation. HV WINDINGS are manufactured with enameled wire or plate covered in true cellulose paper.

3.BUSHINGS

These are the heavy porcelain type, manufactured in compliance with UNEL standards, and are chosen according to the rated currents and the insulation class of the transformer

4.VOLTAGE TAP CHANGER

This switch is placed under the cover and maneuvered externally to

5.TANK

The tank is manufactured in steel sheet and steel profiles with a corrugated or radiator type cooling system.

INSULATING OIL

Shows chemical and electrical characteristics compliant with C.E.I. and I.E.C. standards, dried and de-gassed before filing the transformer.

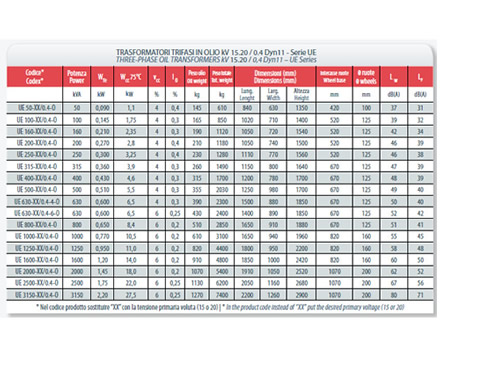

For the technical data of OIL-IMMERSED THREE-PHASE TRANSFORMERS kV 15.20 / 0.4 Dyn11 - EU Series and THREE-PHASE TRANSFORMERS kV 6.10 / 0.4 Dyn11 - ECE Series, download the data sheet below

The production process begins with the realization of the coils, which are one of the fundamental parts of the transformer.

The low voltage windings are normally made of aluminum sheet to ensure better resistance to electrodynamic stress in the event of short circuits; the turns are insulated from each other by an insulating material composed of pure cellulose paper.